The car workshops “Taller Siles” in El Prat de Llobregat and “Duo Mecánico” in Terrassa chose our Modulfix workshop tiles for recurring reasons in their sector.

Why is Modulfix the ideal floor in a car workshop?

When a workshop decides to change the floor of its premises, it faces different problems.

The first of these is the scarcity of options. Specifically, the alternatives being considered are terrazzo or continuous floors (epoxy resin or painted concrete, for example).

The second problem is the time and methods of application of these floors compared to Modulfix PVC tiles.

Both types of flooring (resin and terrazzo) have a very slow application time and must be installed by trained personnel. However, Modulfix tiles are very fast to lay and in many cases can be installed by the customer at his own pace. The 200m2 Siles workshop was installed on a Saturday and was ready to work on Monday without stopping its activity. With a resin or terrazzo, the downtime would have been at least a week.

Many shops complain about other aspects of the above mentioned floors (terrazzo and continuous floors).

Terrazzo tiles can be broken by falling tools or by the building’s own movements.

Continuous floors tend to break, lift or crack due to expansion, grease or humidity, in addition to being contaminable.

Modulfix tiles do not break (they have a very high Shore hardness but are flexible at the same time) and are little affected by workshop fluids (brake fluids, battery acids,…).

In addition, thanks to this flexibility, they cushion the fall of parts to the floor, avoiding the breakage of the part handled by the mechanic.

It is true that resins have positive aspects, especially a clean and continuous floor finish. However, it is worth noting that once laid, Modulfix industrial tiles give this same sensation as the joints are barely noticeable as seen in the photo of the Siles workshop below.

However, other workshops have opted for a new, more striking image, as in the case of the “Duo Mecánico” workshop, which decided to play with colors, as shown in the following photo.

In addition, to personalize the workshop, they took advantage of our Moduprint printing system to put their logo on the floor of the workshop and a couple of “Stop” pictograms, thus delimiting the areas restricted to the public.

Which range of Modulfix tiles should I install on the floor of my car repair shop?

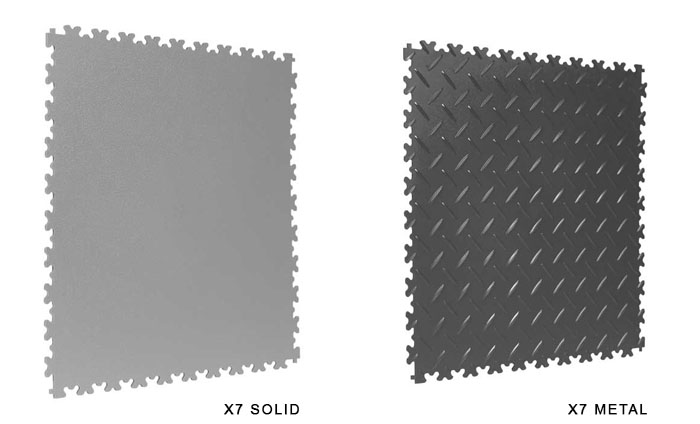

We recommend 2 ranges in 7mm thickness which are Modulfix X7 Solid and Modufix X7 Metal. The difference between these two models lies in the surface of the tile. The X7 Solid range has a slightly textured surface while the Metal range has the appearance of teardrop veneers. Mechanics find the floor pleasant to walk on as it puts less strain on the legs and the floor is not as cold in winter compared to painted concrete or terrazzo.

Cleaning my Modulfix industrial flooring.

We recommend cleaning Modulfix tiles with a rotary machine, a degreasing agent suitable for PVC floors and a brush that is not too aggressive. The dust accumulated on the floor should be swept off first. As with other floor coverings, when an aggressive liquid (gasoline, acids) is spilled on the floor, it is recommended to pick it up as soon as possible, as prolonged contact could leave stains.

⇒ SEE MORE INFORMATION ABOUT MODULFIX GARAGE

OTHER WORKSHOP PROJECTS WITH MODULFIX GARAGE TILES:

⇒ Bus workshop with Modulfix industrial flooring.