Changing the floor of your cold room is complicated for an industrialist.

The main problem is the lack of time since it is usually required to turn off the chamber or tunnel (*). Although the installation of Modulfix PVC tiles also requires this operation, application times are much faster than with resins (epoxy or polyurethane) or painted concrete.

In addition, applying a continuous floor generally involves sanding or scraping the screed, which can cause a lot of dust. In the case of Modulfix industrial tiles, the preparation of the substrate is limited and its flexibility allows an adaptation to the screed even if it is not in perfect condition (in areas of extreme cold, a good planimetry is necessary).

Another reason that causes some concern among industrialists about continuous floors is the ease with which they break, lift or crack due to expansion, extreme cold or humidity.

(*) There are continuous floors applicable at very low temperatures, such as methacrylates, but their high price is an obstacle.

Modulfix tiles do not break (they have a very high Shore hardness but are flexible at the same time) and are little affected by liquids or grease (as they are made of plastic).

It is true that multi-layer continuous floors have some positive aspects, especially a clean and continuous floor finish. However, once laid, Modulfix tiles give this same sensation as the joints are almost invisible as can be seen in the following photo.

Example of a cold room floor in very poor condition prior to the application of Modulfix tiles.

The substrate was repaired with suitable material prior to the installation of Modulfix tiles.

Which range of Modulfix tiles should I install in my cold room?

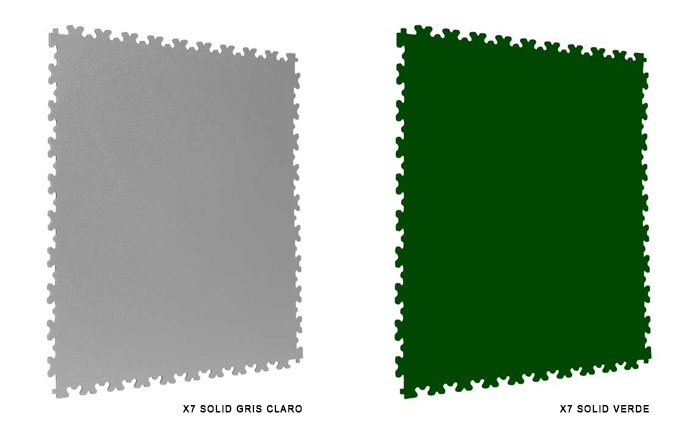

The recommended model is the Modulfix X7 Solid tile (7mm). It is available in 12 colors.

Installation process of Modulfix industrial flooring in a very cold area.

Modulfix tiles must be glued for two reasons. The first is to avoid shrinkage with the strong change in temperature to which they are subjected. The second is to prevent liquids from seeping into the joints and thus have a completely airtight floor. To be able to carry out the gluing, it is necessary to turn off the freezing or refrigeration system (installation at a minimum temperature of +15ºC). Once the flooring has been glued, it is necessary to wait a few hours before lowering the temperatures again.

Installation of Modulfix tiles in freezing tunnels

⇒ SEE MORE INFORMATION ABOUT MODULFIX® FLOORINGS

OTHER INDUSTRIAL PROJECTS WITH MODULFIX:

⇒ New and clean floor in warehouses with Modulfix® tiles

⇒ Modulfix factory floorings, resistant and practical flooring