Why is Modulfix the ideal floor in a factory?

When an industrialist decides to change the floor of his facilities, he faces different problems.

The first is the scarcity of alternatives. Specifically, the options being considered are terrazzo or continuous floors (epoxy resin or painted concrete, for example).

The second problem is the time and methods of application of these floors compared to Modulfix Industry PVC tiles.

Both types of flooring (resin and terrazzo) have a very slow application time and must be installed by trained personnel. However, Modulfix tiles are very fast to lay and in many cases can be installed by the customer at his own pace. Our teams lay 500 to 600m2 in a weekend.

On Monday you can work without having stopped the activity!

In addition, installing a continuous floor often involves sanding the floor, which can cause a lot of dust that is harmful to the machines in a factory. In the case of Modulfix industrial tiles, the preparation of the substrate is minimal and its flexibility allows an adaptation to the subfloor even if it is not in perfect condition.

Before and After without preparation

Many industrialists complain about other aspects of the above-mentioned floors (terrazzo and continuous floors).

Terrazzo tiles can be broken by falling objects or by the building’s own movements.

Continuous floors often break, lift or crack due to expansion, grease or humidity.

Modulfix tiles do not break (they have a very high Shore hardness but are flexible at the same time) and are little affected by liquids or grease (as they are made of plastic).

In addition, thanks to this flexibility, they cushion the fall of parts to the floor, avoiding the breakage of the part handled by the operator.

It is true that not everything is negative and that resins have positive aspects, especially a clean and continuous floor finish. However, it should be noted that once laid, Modulfix tiles give this same sensation, as the joints are hardly noticeable.

Another factor to take into account in a factory is safety and again Modulfix tiles meet the highest criteria. First of all, they have an R10 slip classification (DIN 51130). In addition, the wide variety of colors makes it possible to distinguish zones. Finally, thanks to our Moduprint technology, it is possible to print any image, for example safety pictograms (see below).

Printing of Moduprint safety pictograms

Which model of Modulfix tiles should I install on my factory floor?

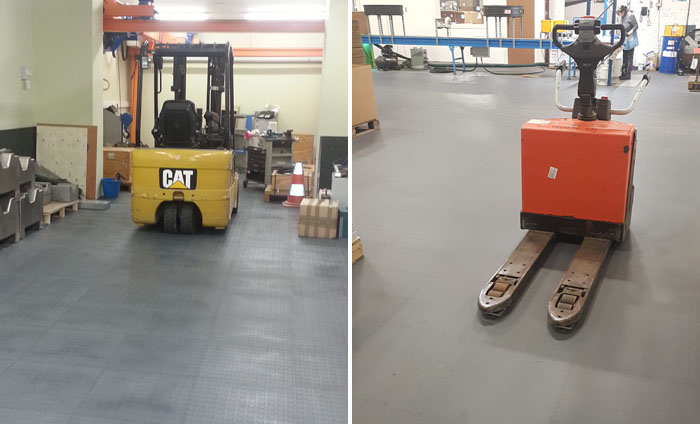

The choice of the right tile is the result of the study of the needs of the industrialist by our technicians. The main criteria we take into account are the weights handled, the type of vehicles circulating in the factory (forklifts, stackers, electric or manual system). In case of small wheels, we recommend the use of plastic wheels instead of nylon wheels.

We have 3 ranges for the industry: Modulfix X9 Extreme (9mm, extra-hard PVC), Modulfix X7 Heavy (7mm, extra-hard PVC) and Modulfix X7 Solid (7mm).

Maintenance of my Modulfix industrial floor.

We recommend cleaning Modulfix tiles with a rotary machine, neutral detergent and a brush that is not too aggressive. It is necessary to vacuum or sweep the dust accumulated on the floor first.

Many users report an improvement after the installation of Modulfix tiles, especially when they had, for example, sandy concrete that was constantly leaving dust.

⇒ VIEW MORE INFORMATION ABOUT MODULFIX INDUSTRY

⇒ CONSULT MODULFIX CATALOG ON LINE

OTHER INDUSTRIAL PROJECTS WITH MODULFIX:

⇒ A clean cold room with Modulfix® tiles

⇒ Modulfix, the industrial floor without building site for warehouses and warehouses