The bus company CFTU in Martinique (French West Indies) chose our Modulfix tiles for the renovation of its 1000m2 workshop floor.

Why did you choose our Modulfix industrial tiles?

The maintenance of their fleet of 100 vehicles is constant and they were looking for a new floor that would prevent them from stopping their activity.

Apart from Modulfix tiles, the alternatives they had were terrazzo or continuous floors (epoxy resin or painted concrete for example).

These floors require a long application time compared to Modulfix PVC tiles and must be installed by trained personnel.

However, Modulfix tiles are very quick to lay and in many cases, can be installed by the customer at their own pace. The CFTU shop was set up in 3 days in zones, so they were able to keep working at all times.

Many shops complain about other aspects of the floors mentioned above (terrazzo and continuous floors).

Terrazzo tiles are often broken by falling tools or by the movement of the ground.

Continuous pavements tend to break, lift or crack due to expansion, grease or humidity, in addition to being contaminable.

Example of a continuous floor in poor condition.

Modulfix tiles do not break (they have a very high Shore hardness but are flexible at the same time) and are little affected by workshop fluids (brake fluids, battery acids,…).

In addition, thanks to their flexibility, they help to cushion objects falling to the floor, avoiding breakage of the tools handled by the mechanic.

The resins have positive aspects, especially at first a clean and continuous floor finish. However, it should be noted that once laid, the Modulfix PVC tiles give this same sensation as the joints are hardly noticeable as seen in the photo of the CFTU workshop below.

In order to customize the workshop, they used our Moduprint printing system to put signage on the floor.

Customized Modulfix workshop floor

Which range of Modulfix floorings should I install on the floor of my commercial vehicle workshop?

We recommend 3 ranges for heavy vehicle workshops. The 7mm thick Modulfix X7 Solid and Modufix X7 Heavy or the 9mm Modulfix X9 Extreme tiles. The X7 Solid should be glued down while the other two, in extra-hard PVC, can be floated (except for direct sun exposure such as entrances). Mechanics find the floor pleasant to walk on as the legs are less loaded and the pavement is not as cold in winter compared to epoxy resin or terrazzo.

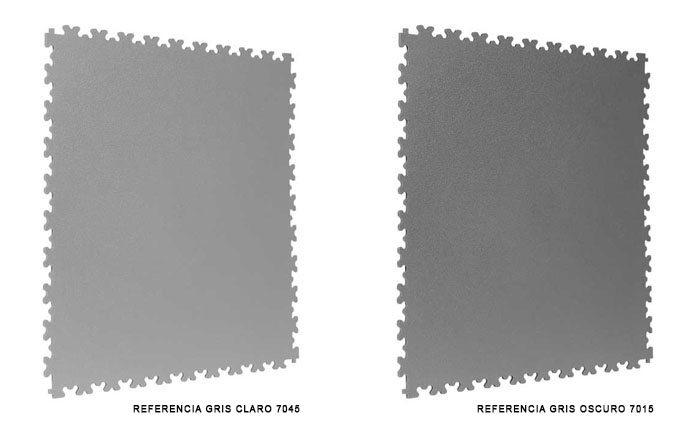

Two colors (Light Gray 7045 and Dark Gray 7015) were used to mark out the passage and work areas. In this workshop, the range installed was X7 Heavy in extra-hard PVC.

Cleaning my Modulfix industrial flooring.

We recommend the maintenance of Modulfix floors with a machine, a degreaser suitable for PVC floors and a brush that is not too abrasive. It is necessary to first sweep the accumulated dirt from the floor. As with other floors, when an aggressive liquid (gasoline, acids) is spilled on the floor, it is recommended to clean it as soon as possible, as prolonged contact could leave stains.

⇒ VIEW MORE INFORMATION ABOUT MODULFIX

⇒ CONSULT MODULFIX CATALOG ON LINE

OTHER WORKSHOP PROJECTS WITH MODULFIX TILES:

⇒ Car repair shops in Barcelona choose Modulfix PVC tiles

⇒ ITV de Asturias after 5 years with Supreme Floors industrial tiles